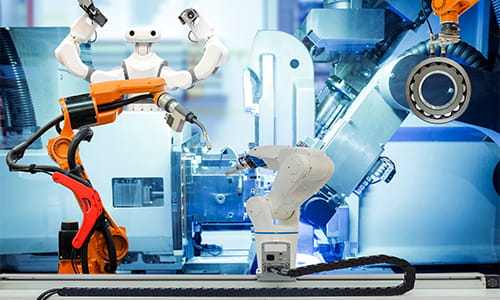

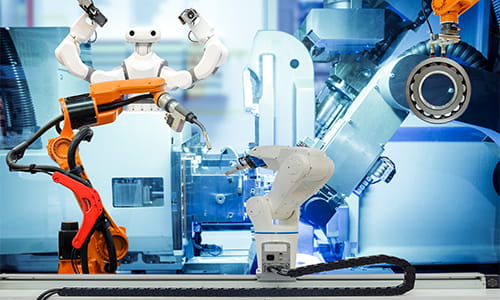

Automated Robotic Solutions and Complete Robotic Systems

With skilled labor harder to find and retain, many warehouses and manufacturing facilities are implementing automated robotic solutions into their operations. And with recent technological advances, it’s now possible to automate small batch runs and sensitive, difficult components once thought impossible or too costly to automate.

-

Although automated robotic systems and solutions are becoming more prevalent in the industry, many facilities aren’t sure where to start when it comes to automation. That’s where we come in.

Although automated robotic systems and solutions are becoming more prevalent in the industry, many facilities aren’t sure where to start when it comes to automation. That’s where we come in.

When you implement a turn-key robotic solution from Pengate, we’ll lead you through every step of the process—from initial design and simulation to project management, installation, and follow through. Start with a single-robot cell or take on a complete robotic material handling system and watch your productivity increase.

Common Applications for Automated Industrial Robotics

Automated robots and robotic systems are designed to be integrated into your operations with a specific task in mind, and are tailored to meet the unique needs of your business. Here are six common applications for integrating automated robotic systems.

-

Robotic Welding Robotic welding is highly productive for completing high-volume, repetitive tasks in your operations. Some of the most common processes for robotic welding are arc, resistance, spot, TIG, MIG, laser, and plasma welding. Welding robots are both easy to program and able to help address the growing skills gap in the welding industry. -

Robotic Packaging Automated packaging robots are flexible and easy to integrate into your operations. They're designed to help reduce part-package time and quickly lift larger, heavier packages. With proper end-of-arm tooling, packaging robots can complete nearly any process. Choose from a variety of sizes, mounting options, and reach availability. -

Robotic Pick & Place Take advantage of uninterrupted speed and guaranteed reliability and accuracy with our automated pick-and-place robots. Built for maximum repeatability, pick-and-place robots are guaranteed to increase productivity in your operations. Plus, they're easy to implement and can be customized to fit your unique needs and requirements. -

Robotic Dispensing Designed with precision and uniformity of performance in mind, our automated dispensing robots work in unison to streamline your production processes and create a well-engineered, final product. With robotic dispensing, you can ensure product is released evenly and efficiently, all while decreasing waste and reducing downtime. -

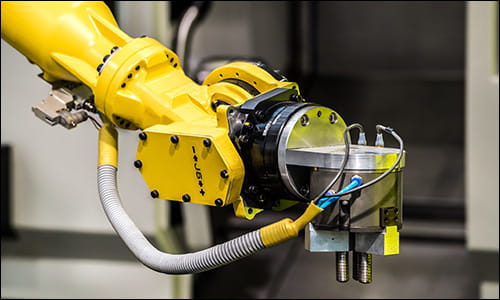

Robotic Cutting Increase speed while maintaining extremely precise and accurate cuts with our automated cutting robots. Each robotic cutting system can be customized with pre-engineered cutters attached at the arm, and are guaranteed to decrease cutting errors and reduce product waste while simultaneously increasing your overall productivity. -

Robotic Non-Destructive Inspection (NDI) Maximize your productivity while maintaining the reliability and integrity of test performance and data acquisition with our automated NDI robotic solutions. Designed for manufacturers in the aerospace or defense arena who must meet strict safety standards, NDI robots deliver the highest level of accuracy and repeatability.