Zoned for Greater Productivity

High-throughput warehousing and distribution operations are constantly challenged to save space, time and money at every turn. Racks are getting higher. Aisles are getting narrower. Inventories are getting larger.

At the same time, skilled lift truck operators are in short supply and inexperienced employees are often required to meet seasonal demands. To maximize throughput and productivity, you need to minimize pick errors and variability. Zoning provides a fast and simple solution for improving consistency and efficiency.

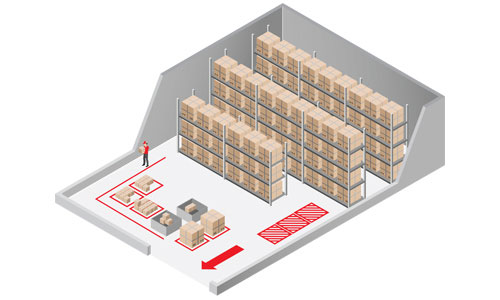

Zoning ensures more consistent and reliable truck operation by controlling and restricting certain truck parameters - including speed and lift height - at precise locations in specific aisles. RFID tags embedded in the floor transmit instructions to your trucks, overriding manual controls to reduce the effects of human error and differences in operator skill, minimize truck and facility damage by avoiding collisions with known obstacles and increase picking speed and efficiency without compromising accuracy.

More Manageable Forklifts. More Profitable Operations.

By tailoring each truck's performance characteristics to specific locations within your warehouse, zoning can enhance productivity and profitability throughout your entire operation. It also minimizes the variability between operators for more consistent and efficient order picking.

Enhanced Confidence

Greater Security

Superior Picking Accuracy

Reduced Costs

-

Enhanced Precision, Productivity & Profitability

Zoning controls can be customized to the unique features and demands of your environment, allowing your trucks to automatically adapt to:

+ varying ceiling heights

+ no entry areas

+ pedestrian cross walks

+ racking irregularities

+ safety zones

+ congested areas

Paired With The Most Popular Order Pickers in North America

Raymond 5500 & 5600 Orderpickers are ideal for high-throughput applications, offering quick acceleration and fast lift speeds for enhanced productivity. Delivering smoother handling, greater energy efficiency, and longer component life for a more comfortable, reliable, economical operation.

-

With the broadest range of capabilities available in the market, the 5500/5600 order pickers can adapt to a variety of warehouse environments, load sizes, and applications. They also allow you to optimize storage capacity by operating in narrow aisles and at high picking levels.

With the broadest range of capabilities available in the market, the 5500/5600 order pickers can adapt to a variety of warehouse environments, load sizes, and applications. They also allow you to optimize storage capacity by operating in narrow aisles and at high picking levels.

An exclusive ACR System™ delivers industry-leading lift, lower, and travel speeds, and easy-to-use ergonomic controls enhance operator comfort for greater productivity.

Get in the Zone Today!

If you're interested in learning even more about our Zoning Solutions for Raymond Order Pickers, complete the form below and we'll be in touch soon to further assist.